Sensor technology from Leuze makes an important contribution to an efficient and safe production line process at BMW Group Plant Leipzig.

With sensor expertise for high-voltage batteries

The site produces both combustion engine and electric models in parallel. E-mobility requires high-voltage batteries to supply the BMW Group’s electric cars or hybrid vehicles with the necessary drive energy. The automotive group also manufactures these on site. Sensor technology from Leuze makes an important contribution to an efficient and safe production line process, implemented by Schaeffler Special Machinery, the Schaeffler Group’s mechanical engineering company.

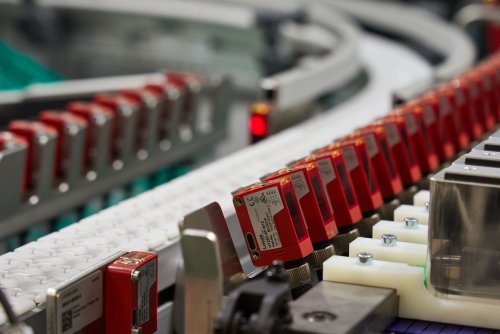

A robot places the cells removed from a large load carrier (GLT) onto the conveyor belt. Here, horizontally installed switching light curtains from the CSL series detect whether the cells are positioned correctly.

It all starts with the cell

Three successive production steps are required from the first component to the finished high-voltage battery. Only after cell coating, module production and finally assembly is a high-voltage battery ready for use as an electric vehicle’s energy supply. Precision and reliable processes are essential at every step. Leuze supports this with sensor solutions in cell coating and module production. Cell coating is the first step in high-voltage battery production. Each battery module consists of several cells. These are delivered to BMW in large load carriers (GLT). So that the GLTs can be unloaded automatically by robot, a Leuze MLC safety light curtain secures the danger zone to prevent people from entering. Muting ensures that only the GLT can pass through. The robot always unloads 16 cells at the same time and places them on a conveyor belt. Here, horizontally installed, Leuze CSL switching light curtains detect whether the cells are positioned correctly. “The switching light curtains particularly suitable for monitoring large detection fields as they are easy to install, configure and far more cost effective than image-based systems” explains Jürgen Schweiß, KAM-Automotive and Safety Application Specialist at Leuze.

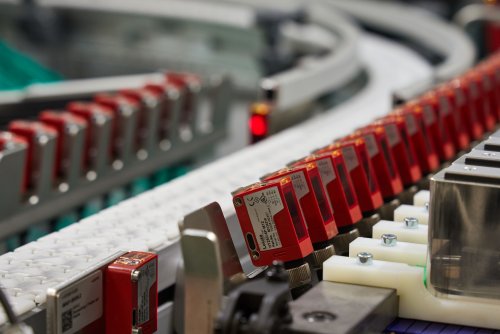

Advantage of using Leuze 25C series sensors: They detect the high-gloss surface of the cells with absolute reliability.

High-gloss surfaces

Diffuse sensors from Leuze are implemented at different points: “Sensors mounted on the belt detect the presence and correct position of the cells. If they are present and correctly positioned, the process continues,” says Jürgen Schweiß. The advantage of the PRK 25C series sensors used here is that they can detect the high-gloss surface of the cells with absolute reliability and can installed even in confined spaces due to their small physical size. Despite its small size the sensor has an operating range of 16 meters. Another advantage is that the sensors can be easily adjusted for sensitivity and alignment due to their bright light spot.

The blue-colored cells on their way to the next production step. Sensor technology from Leuze always has everything in view. The HT46CL background suppression sensors detect the individual cells and control the conveyor belt.

A compact approach to safety

Sensor technology from Leuze keeps an eye on every aspect of cell coating: Laser diffuse reflection sensors from the HT46CL series detect the individual cells and control the conveyor – with maximum detection reliability thanks to background suppression. Before the cells are loaded into a GLT, they are discharged through a Leuze MLC safety light curtain. Advantages of Leuze light curtains: They not only score points with their high resolution, protective field height and operating range, as Jürgen Schweiß emphasizes: “With light curtains, a compact design and short safety distances are also important. This allows them to be easily integrated into tight installation situations.”

To ensure that the large load carriers (GLT) can be loaded and unloaded safely, a Leuze safety light curtain from the MLC series secures the danger zone to prevent people from entering. Muting ensures that only the GLT can pass through.

Perfectly positioned

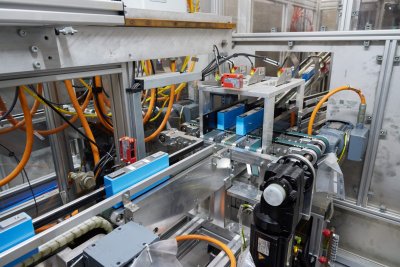

Leuze laser diffuse reflection light scanners also monitor the unloading of the cells from a GLT into a module line from Thyssenkrupp Automation Engineering. Each cell also receives a “heat shield” – a protective heat insulation – which is pressed onto the long sides. Robots rotate the cells into the desired position on a circular machine. Sensors from Leuze also provide support here: PRK 25 retro-reflective photoelectric sensors detect the presence of the objects. The heat shield process runs in parallel at two stations in order to achieve a high throughput time.

When the cells are separated, sensors detect the positions of the objects. This is a prerequisite for an automated process

From stacking to the module

In “stacking”, as experts call the stacking of several cells to form a battery module, several cells are placed next to each other and a pressure plate is attached to each end. PRK 25C sensors from Leuze detect the height and presence of the cells and recognize whether the tool carriers are closed correctly. Sensors are also used when placing the cell contact system (ZKS) on the module. A machine lifts the entire module so that the coating on the cell base can be checked: “Here, Leuze sensors provide support for height detection and at stop positions” says Schweiß.

At this station, each cell is given a “heat shield” – protective heat insulation – which is pressed onto the long sides. Leuze PRK 25 retro-reflective photoelectric sensors detect the presence of the objects.

Everything in sync

Leuze sensors perform important tasks in the cell coating line and module production at the BMW Group plant in Leipzig: They reliably detect objects and also meet high requirements, such as the detection of high-gloss surfaces. In addition, safety technology from Leuze ensures seamless safety on machines and systems. The Sensor People thus contribute to efficient processes in the automotive industry and are always on hand to support system operators in the design and implementation of sensor and safety solutions.

About Leuze

With curiosity and determination, the Sensor People from Leuze have been creating innovations and technological milestones in industrial automation for 60 years. They are driven by the success of their customers. Yesterday. Today. Tomorrow. The technology leader’s high-tech product range includes a number of different sensors for the field of automation technology. Among these are switching and measuring sensors, identification systems, and data transmission and image processing solutions. As a Safety Expert, Leuze is also focused on components, services and solutions for safety at work. Leuze concentrates on its core industries, in which the Sensor People have extensive, specific application know-how and many years of experience. These include intralogistics and the packaging industry, machine tools, the automotive industry as well as laboratory automation. Leuze was founded in 1963, headquartered in Owen/Teck in Southern Germany. Today there are more than 1400 Sensor People around the world who are working with determination and passion for progress and transformation to make their customers successful in a constantly changing industry. Regardless of whether in the technological competence centers or in one of the 21 sales companies, supported by more than 40 international distributors.